Page 92 - FoodFocusThailand No.231 June 2025

P. 92

ST

STORAGE, HANDLING & LOGISTICSORAGE, HANDLING & LOGISTICS

Advancing Toward Industry 5.0:

Intelligent Automation and

Robotics in Warehousing

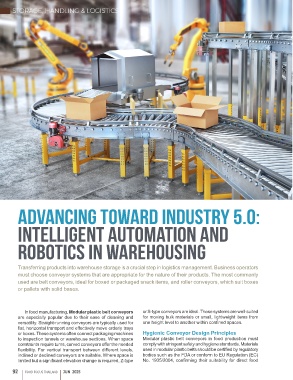

Transferring products into warehouse storage is a crucial step in logistics management. Business operators

must choose conveyor systems that are appropriate for the nature of their products. The most commonly

used are belt conveyors, ideal for boxed or packaged snack items, and roller conveyors, which suit boxes

or pallets with solid bases.

In food manufacturing, Modular plastic belt conveyors or S-type conveyors are ideal. These systems are well-suited

are especially popular due to their ease of cleaning and for moving bulk materials or small, lightweight items from

versatility. Straight-running conveyors are typically used for one height level to another within confined spaces.

flat, horizontal transport and effectively move orderly trays

or boxes. These systems often connect packaging machines Hygienic Conveyor Design Principles

to inspection tunnels or warehouse sections. When space Modular plastic belt conveyors in food production must

constraints require turns, curved conveyors offer the needed comply with stringent safety and hygiene standards. Materials

flexibility. For vertical transport between different levels, used in modular plastic belts should be certified by regulatory

inclined or declined conveyors are suitable. Where space is bodies such as the FDA or conform to EU Regulation (EC)

limited but a significant elevation change is required, Z-type No. 1935/2004, confirming their suitability for direct food

92 FOOD FOCUS THAILAND JUN 2025

23/5/2568 BE 17:16

88-94_Storage Handling_����.indd 92

88-94_Storage Handling_����.indd 92 23/5/2568 BE 17:16